Situation - Most platters charge a bulk rate for their zinc and gold zinc plating. Basically all that can fit in the barrel for one base minimum charge ($75-100 around here) but will charge an additional minimum charge if you want two different finishes. A few years back Jack Brooks of DeadNutsOn (website) offered a solution to me and its taken this long before I did some more plating to try out his suggestion.

The basis of this idea is that to produce zinc dichromate finish the parts first must be zinc plated (clear, bright or silver - what ever your local term is) before the parts are placed in a dye bath. What was suggested was that you get all your parts zinc dichromated then simply removed the gold dye for those items that you need just zinc.

What you'll need:

Container to hold the liquid for the bath

Vinegar

Tap water

Dichromated parts you want to process

Here is some pictures of the process I used

Step #1 - Plate parts

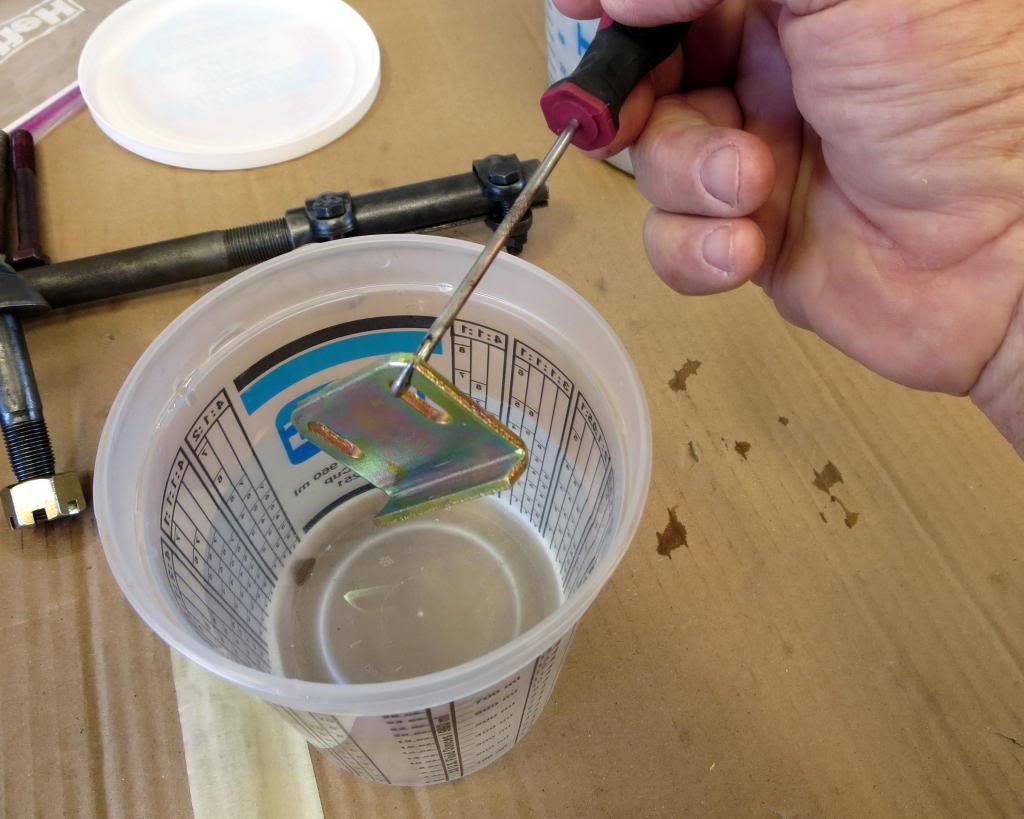

Prepare the bath -

Prepare the bath - In a container mix a solution of 50% vinegar and 50% water. Enough to cover the parts (individually or as a batch) once they are submerged in the liquid solution

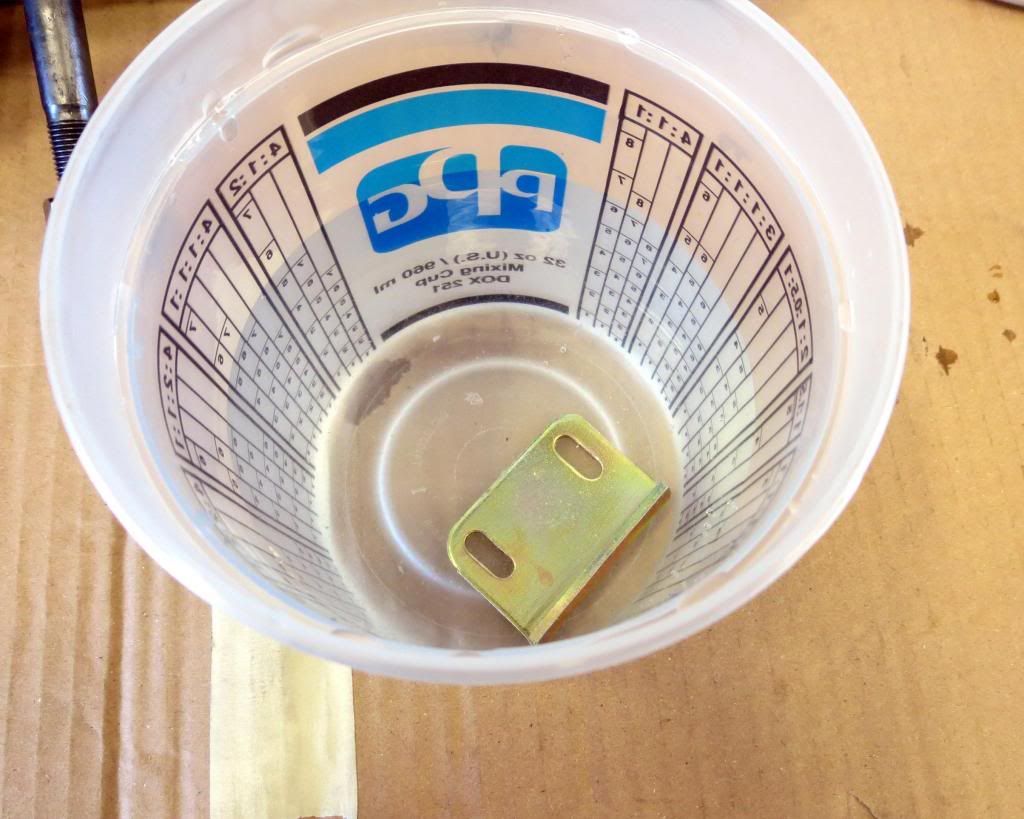

Place the part/parts in the solution.

Place the part/parts in the solution.  Soak and Strip -

Soak and Strip - Allow the part to soak for 3-4 minutes. You can always re-dip the item if the removal is incomplete but if left too long the vinegar can strip all plating from the part. I know

You can agitate the liquid and parts around during this process. I my efforts didn't seem to change much or speed up the process

Remove -

Remove - the part and clean/flush with water, in a parts washer or another bucket. Sometime the use of a soft brush will help in the corners and remote nooks of the item.

Dry the part and use or store.

Dry the part and use or store. Zinc, when exposed to air will oxidize producing a softer less shinny finish unless you oil or wax the part. Same thing goes for the unstripped zinc dichromate parts as the gold finish can diminish over time unless protected. Here is a sort of - before and after picture. Hope this helps others.