So something around 7T247xxx

Unfortunately finding rust free NJ cars can be difficult so my sampling is not as great with them. The closest I have is from 7T02C2377xx but didn't get an opportunity to get many pictures of that car. If you look closely you will see body color over sound deadener in the rear wheel wells - common at all three plants for that year and the years before. Same rough and heavy application of up to 1/4" thick in places.

I believe the practices were pretty similar through out the year at that plant from what I have seen so in that spirit I offer some pictures from a really nicely preserved car from early in the year that should help point out some of NJ practices that year. Took over 60 pictures just of wheel wells on this one

Just lucky some NJ cars moved west early in their life.

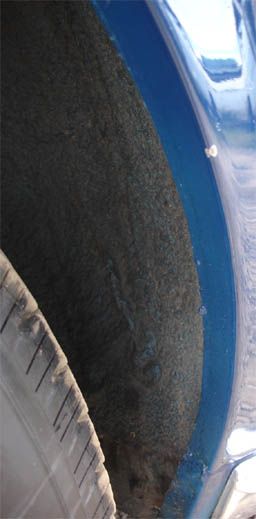

As usual the worker painting the rear quarters got allot of paint on the rear wheelwell forward, rearward and back surfaces as well as the frame rails exposed in the rear wheel well. When cleaned the paint is as glossy as the exterior on the frame surfaces. In these pictures you can see the lower/bottom pass of the sound deadener applicator and how if starts and finishes on the frame rail and does not stop right at the edge of the wheel well magically as we often see (and deduct for) on many restored cars

Looking forward and out towards the lip (top edge of the wheel well) you can see that a worker applied a swipe of seam sealer with a brush or rag along the radius of the wheel well just above the lip. I've got no idea of the purpose for this application but we see it at all three plants at one time or another..

In this short I dug a little sound deadener away to see what lay under it - nothing just bare steel.

Also notice that the sound deadener was not applied all the way to the edge of the wheel well (again like we see on many "restored cars") but instead back about 4" at the top of the radius. I believe the worker stayed away from this edge since a slip with chance the possibility that the product would be sprayed outside of the wheel well landing on other parts, cars or panels nearby - causing more work and clean up

Second pair show the brush applied seam sealer in green and the sound deadener application in purple

Hope this helps you towards your goal