Cleaning 2100/4100 carburetor bodies and covers without permanent surface changes.

Most people will realize that as die cast aluminum surfaces get modified permanently if any hard media blasting, tumbling with media polishing, wire brushing, or vibration with any kind of media polishing gets done. Strong mineral acids and strong bases can etch away aluminum too.

It takes a lot of time and steps but I like to clean bare aluminum carburetor castings without any of the methods above. I would really like to try dry ice blasting to deep clean the original surfaces but so far I have not found a shop anywhere close to discuss such work with.

In the mean time I thought I would show you some examples.

On the left below is a new old stock 1965 model year carburetor assembled in the summer of 1964. Ex-dealer stock somebody robbed it of parts long ago but it stayed very clean and all the factory paint and grease pencil markings are still present for parts still there. On the right below are a used body and cover for a C3OF-AJ carburetor I am working on for a friend. No, it is not possible to get just out of the mold appearances for old used aluminum parts but if no one has damaged them and they do not have corrosion from something like antifreeze/coolant they usually clean up pretty well.

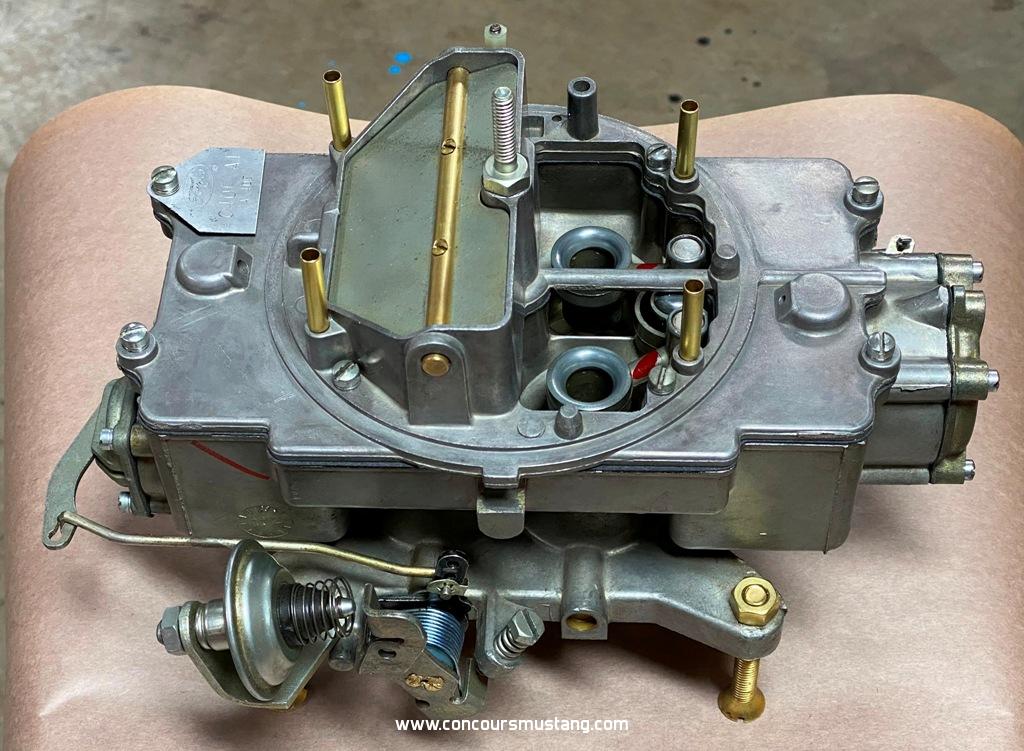

The C4OF-AT carburetor below is not what I call a restoration. Cleaning removed all factory paint daubs and grease pencil marks so I did try to recreate all of them accurately. (The owner supplied the freshly replated air cleaner stud shown.) I cleaned and serviced it for an old friend. The worst stain it has is a dark line across the choke plate from antifreeze/coolant corrosion.

My process set is a long one. I spent 9+ hours masking, cleaning, dealing with gasket flange burrs somebody created before I got it, testing all the threaded holes, testing relative flows through all calibrated orifices, and gently chemically cleaning all the brass orifices and tube bores the body and cover for the C3OF-AJ carburetor above. (It is best to never run metal anything through calibrated fuel and air passages. The tiniest scratches or burrs can seriously affect in use air and fuel flows. Holley Carburetor Company use to give a document to racers that mentioned what their research results on damaged orifices were. I inspect every calibrated orifice under a very well lighted binocular microscope. Any removable orifices with any scratches or burrs go into the trash. Limited repairs can be made to orifices that do not come out or out easily. Vacuum pickup tubes in 4100 cover assemblies often need some amount of repair and often correction of angles and position relative to the auxiliary venturi to get in the factory specification location.)

Almost anything metal arriving at my work bench starts with a soak in WD40(R) lubricant for a day to two weeks depending on how soiled the assembly or part is and what the crud is. Small parts get immersed and soaked in sealed containers. Large parts get sprayed and sealed in plastic bags.

4100 carburetor bodies and covers are reduced to everything that comes off without drilling, pulling, or pressing. Electrical circuit cleaner is used to check that all passages are open and if applicable left and right side orifices appear to flow the same amounts. Disassembly is followed by a hot Dawn(R) detergent and water hand wash. After water rinsing at least three times, low pressure compressed air use speeds up complete drying while that parts are still warm.

The preparation for body and cover cleaning takes a long time. Every threaded hole gets something installed (old used parts I keep for the task, jets and valve body bores get sealed) to protect internal threads. Every soft aluminum and lead alloy core plug gets covered with four layers of thick aluminum foil adhesive tape rounds, the remaining small passages get multiple tape layer protection, and the fuel rail soft core plugs get an added electrical tape round covering each one of them. Tubes are covered with snug fitting rubber cap plugs. The vacuum secondary passages in the cover and body get sealed.

Once the body and cover are masked well used walnut shell pieces are utilized to medium air pressure media blast every surface they can get to on the body and cover. New bare aluminum obtains a microscopic layer of aluminum oxide film just being exposed to air. Exposure to heat cycles and many chemicals accelerates and extends the oxidation process and over time the oxide layer not only gets a little thicker but it traps foreign materials like road dirt, oils, antifreeze, and residues from fuel allowed to get on the outside of carburetors. The dirty oxide layer is somewhat brittle and being very thin the walnut chips knock most of it off the parent aluminum underneath. I a twist of fate carburetors that got very dirty very quickly with oil, road dust, and or fuel stains in their service lives often have the most original looking surfaces once the crud gets removed. Any oily fuel stained surface gets projected from further air exposure degradation.

After walnut shell blasting all the masking tapes, caps, and threaded devices are removed. The parts go to get hot detergent and water washed again. The pressed in calibrated brass parts get cleaned chemically inside and out before final rinse and blow dry. I get a liquid brass cleaner at the grocery store. If some trouble areas need scrubbing I do it with very fine bronze wool lubricated by soap and water.

Passages had liquids through them during testing and cleaning but before calling the bodies and covers done and ready for reassembly I use WD40 to verify all passages still flow as they should.

How about the other parts? For just a service everything gets cleaned gently. Some defects can be repaired and some cannot. Most of the carburetors I service require some number of replacement parts. My only way to come up with good used parts is to buy other cores made in the same time frame and render them down into small parts. Like many other Ford parts and assemblies the parts carburetor bodies and small parts changed over time. Some parts were used only in certain time frames or certain carburetor assemblies in a time frame. Parts designs changed. Body castings changed. Platings and finishes changed. Even the stamps used to number carburetor bodies changed over time. To return an unmolested carburetor to day one configuration is not difficult. Returning one that has been commercially redone can be quite a challenge. One friend bought a "restored" 4100 carburetor from a world famous shop. The body, cover, and throttle plates were correct for the carburetor assembly and assembly date but nothing else was. Every threaded part was either a reproduction or from some other carburetor. I kept the body, cover, and throttle plates but everything else was replaced with good original parts of the correct engineering numbers and time frame. Whew!