Holley (R) Vacuum Secondary Diaphragm Assemblies Are Not All The Same.

1) Original assembly line production parts and genuine Holley brand service parts.

I will avoid the fine original assembly line parts details for now but functionally be aware that there were multiple models of vacuum secondary diaphragm assemblies used in 4150/4160 series carburetors made between the mid 1950s and 1960s (and beyond) that come to play in various Ford powered vehicles. A critical dimension was the quoted length of the operating rod. Three lengths of rods were used in a variety of popular 1950s through 1960s and beyond Ford-Holley carburetors: 2.047 inch, 2.054 inch, and 1.970 inch.

It is very important to use the model (a.k.a. length of rod) diaphragm assembly that was designed for a specific carburetor. Failure to use the correct length for a carburetor design can lead to issues with the secondary throttle subsystem.

The last two Shelby car related carburetors out of high cost "restorations" I serviced prior to use for friends both had the same problem. Both units had longer than original rods in them and neither secondary system would open beyond about 80%. That is they would have never opened all the way on a running engine of any size. The longer than stock rods mechanically prevented the secondary shaft from turning any more towards full wide open throttle.

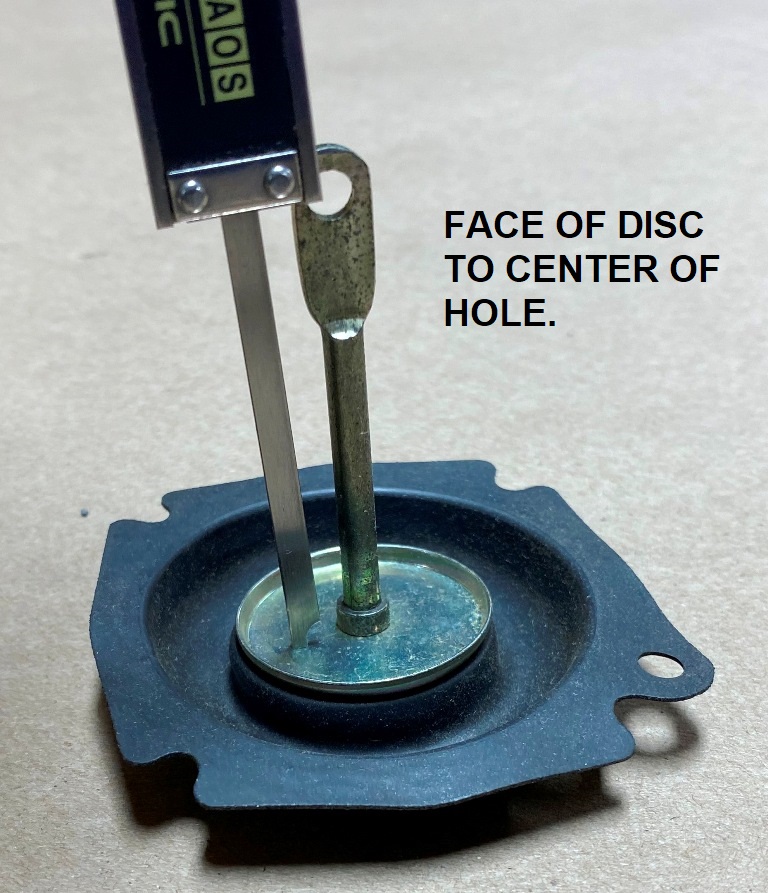

The quick check on the work bench is the distance from the big disc's face to the center line of the pin hole. (My picture of this 1960s new old stock part is not that great but you get the idea I am sure.)

The Holley carburetors I work on the most are the R-3259/R-3259-1 families of carburetors 1964-1967. This family was designed to use the 1.970 inch long rod. The recent 1967 GT350 carburetor I serviced after its expensive "restoration" had an aftermarket diaphragm assembly with a 2.029 inch long rod! That is 3% too long for a critical part. The rubber membrane was also stiffer and thicker also, more on this topic next. (Teaser: The secondaries as received would not move during testing, would not move even with some finger help on the lever. With a longer than stock rod and wrong rubber the secondaries might as well have been welded shut.)

2) Aftermarket replacement diaphragm assemblies.

There have been and still are multiple makers of replacement assemblies. Any rebuild kit or parts not sourced through Holley is likely to have somebody's replacement secondary diaphragm assembly in it. I find two issues with aftermarket diaphragm assemblies; a) rod lengths may or may not match anything provided by Holley and b) some have had and still have significantly different rubber membranes.

The errors in rod lengths are straight forward. The rubber membrane might be less obvious unless you specifically check what you have in your hand. The rubber stock used in genuine Holley parts back when and now measures 0.020 inch thick nominally. The rubber compound is also very soft and compliant. It is fairly common to find aftermarket parts made with stiff rubber 0.025 inch or more thick. 0.020 inch to 0.025 inch in thickness is a 25% increase in rubber thickness. Thicker rubber is stiffer and then add to that to a stiffer rubber compound and some aftermarket diaphragms will never start secondary operation on any size engine.

GT350 wise 1965-67, add rod too long, rubber too thick, and rubber too hard and it is no surprise some users find their secondaries never seem to do anything.

Note: Having secondary diaphragm assemblies incorrect in any way is a problem set. Over time the vacuum secondary housing may have been replaced by an incorrect version, models with check ball might be missing the ball or the ball might be the wrong size, you might have the correct housing but somebody made modifications to the passage, ball seat, and or air bleed if applicable. Last but not least, somebody may have modified (cut or stretched) the original diaphragm spring or installed weaker or stronger springs. I have found all these problems in used carburetors, even "restored" ones.