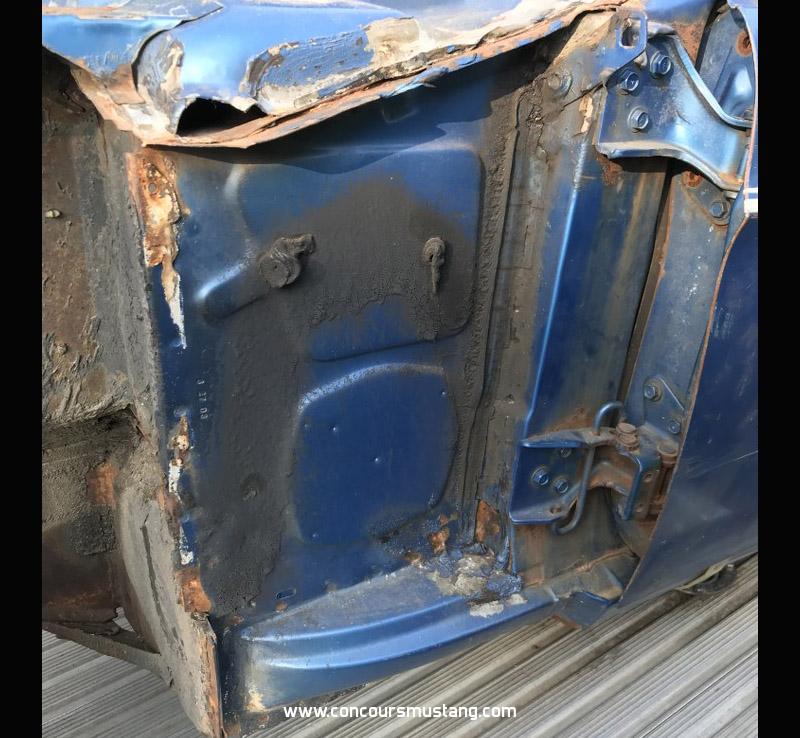

......................... Notice the extra flourish of spray tar in the LH wheel well on top of the paint. I think this indicates the guy was waiting for the front fender to come and be installed because normally the final tar spray seems to have been with the fender in place and aimed front, rear and up.

Respectfully disagree. The application of sealer on the drivers side cowl lower section is typically found on all 1968 Mustangs and Cougars built at all plants

The purpose of that application is to seal a number of holes and retainers side as for the electrical loom on that side of the interior and had no connection with the fender installation or sound deadener applied to the front wheel wells. Fenders and splash shields were not sprayed with sound deadener directly after they were installed on the car. Lots more parts to install before that took place.

You can see in the pattern where a build up around one of the mounting holes that was sealed has fallen off since it was possibly built up around that post or came lose when someone removed that wire loom inside the car. Often you find this application as quick spray "dots" but in this example the specific worker covered the required points with a single pass. What I do find interesting and different is that for some reason for at least part of the 68 production year workers applied some thick different type of chalk or dum-dum over those holes before applying the spray over those points.

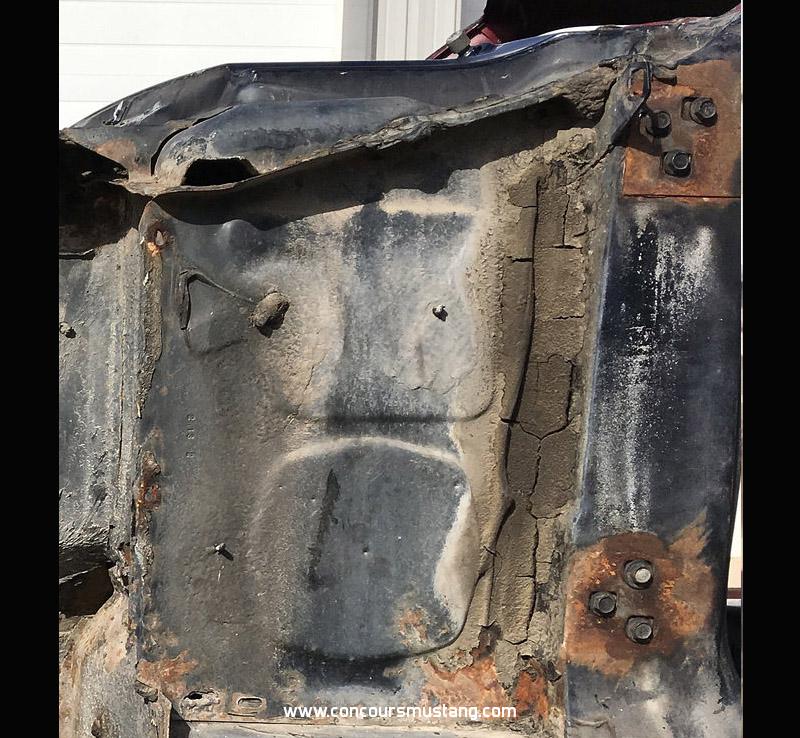

Another example likely applied by the same worker. This picture shows the three post/attachments I believe were the focus and purpose of the application. On this one it appears the the guy doing the forward sealant may have applied sealant on one of the post suggesting to me that this is likely just a practice of may be one worker on one shift and he didn't get, always all the posts, post every time but does suggest the material, when the chalking sealant was applied, if it was and who was responsible for the practice

Another example where you can only see part of the area but shows a heavy application of sound deadener to the splash shields as you found on your example

And another that did not include the long curved pattern. Possibly different shift and worker

Passenger side did not have these holes or retainers so no need for the same application there

I believe this quick couple of second application of the spray product there on the cowl, was possibly done by the Dearborn worker assigned to the sealing of the firewall openings and attachment points given that its make up. The material is different form earlier years and some plants but at Dearborn the material is closer to what was used for the firewall sealant purposes