Holley(R) Le Mans Fuel Bowl Accelerator Pump Cover Leak

In the 21st Century another recurring problem started showing up with any of the Holley Carburetor Company(R) carburetors using the original design "center inlet" fuel bowls (a.k.a. Le Mans bowls at a later date.). Multiple Ford and a few Chrysler racing carburetors used these type bowls 1963-1970.

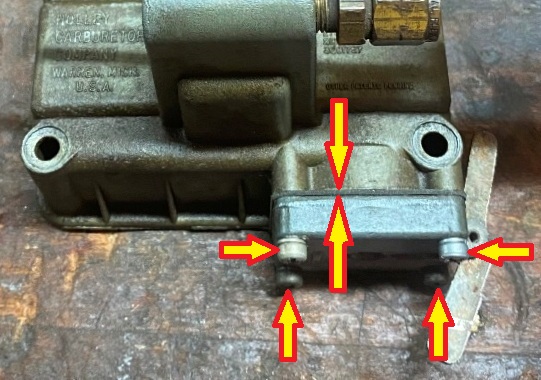

A number of factors seem to contribute to fuel leaks at the accelerator pump cover. In no particular order:

- Some accelerator pump diaphragms are just a tiny bit thinner around the gasket flange than 1960s one OR it take more clamping force to get a leak free interface.

- The faces of pump cavities in some bowls appear to have had their surfaces filed or machined during a 'restoration'. (This reduces the threaded depth of the holes in the face.)

- Not every threaded hole in the pump cavity face is threaded as deeply as the others; or two might not be fully threaded.

I test for leakage at the cover and bowl interface during assembly. Sometimes, even with over tightened screws, diaphragm is clearly not being gripped well at all four screw locations. Sometimes an assembly that does not leak today will if tested again before shipping the unit off; the grip on the diaphragm apparently relaxed by cold flow. Sometimes a carburetor does fine for weeks to months and then starts leaking.

During one of my work bench sessions I used a screw and checked how far it threaded into each hole of two different bowls. I was surprised that at least one hole in each was not threaded as deeply as its neighbors. Over time I found it pretty common to find two holes per bowl not threaded as deep as the other. Making measurements and doing the math it was clear that some new diaphragms would never be held firmly unless a solution was achieved.

While examining threaded holes under a microscope I saw that none of the holes in any unmolested bowl I inspected were threaded to the complete depths of the holes. (It is also important to not have debris packed into the bottom of the holes.) My solution for the carburetors I service was to carefully use a bottom tap and appropriate tapping fluid to extend the threads in each hole to its bottom. I have done more bowls than I can recall and I have talked several car owners through doing the same tasks themselves.

All that work on getting good clamping did not completely solve the issues if a Holley brand ethanol resistant diaphragm was installed. In about half the cases the flange on the diaphragm relaxed a little over maybe six months to a year and if then a slow fuel weep started. Resnugging the cover screws usually stopped the weeping fuel problem from then on.