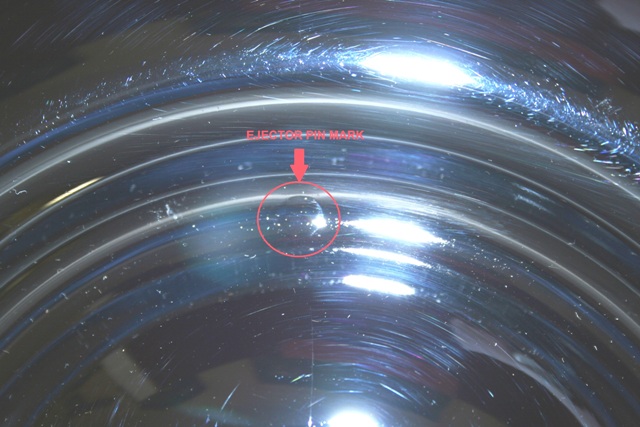

The lid may or may not be an original, can't tell from the pictures posted. If it is an original and not refinished there should be some stamping die defects present. The stamping die set for the "tuned" (a.k.a. double hump) lids had four each "ejector" pins in it to assist getting a just stamped part off the tooling. Depending on when the parts were made the tooling condition left slight marks to very noticeable marks in the steel. Said another way, the contours of the pin ends and the holes they recessed into were sometimes very good (but not perfect) and sometimes they were pretty rough based on the damage to lids seen over the 1963-65 time frame.

The producer made no attempt to work out the metal defects prior to plating. Most plating shops will do their best to make them go away. The typical original unmolested used or new old stock service lid has four damaged places per lid. Reproductions do not so far.

I will cut and paste my commentary on this type air filter assembly below. My notes are specifically for Cobras but since this type air cleaner overlapped into Mustangs most of it applies most likely. Some non-Cobra applications used based painted gold. I have come across service bases that were painted gold first and subsequently repainted black.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

A. Air cleaners.

a. 4V equipped engines used the same chrome plated double hump lid “tuned” assembly as used for 289 High Performance Fairlanes. If the base had a nipple for a clean air supply for a choke pull off it was blocked with a rubber cap and not used.

i. Base

1. Stamped steel painted high gloss black on the side facing the engine. The side facing the filter element was bare steel not painted on purpose, but received highly variable amounts and patterns of over spray. Bases have been seen with just a few black speckles of overspray to wide bands of spray pattern overspray. The round boss formed in that fits the carburetor tops often is not painted on the inside rolled surface not perpendicular to the bottom surface, i.e. paint didn’t get to places not in a straight line of sight from the paint spray gun.

2. Corrosion Problem: Because the element side was not painted (other than chance overspray) used parts are nearly universally rusted. Because there was apparently no chemical pretreatment of the part prior to painting the bottom side the bases are not very corrosion resistant. The lack of chemical pretreatment on these parts during manufacturing means that most, used or new old stock in their original shipping packages, will normally have some degree of filiform corrosion present. (Corrosion and Degradation of Engineering Materials; G.M. Scamans, R.G. Buchheit, in Shreir's Corrosion, 2010: Filiform corrosion may be considered as a specific type of differential aeration cell corrosion that occurs from defects…on painted or coated metal surfaces. Filiform corrosion attack has a unique appearance that resembles fine filaments (worm-like threads) emanating from one or more defects in semi-random directions.)

ii. Element

1. The inner metal wire screen was marked with large ECJ-9601-C2 engineering number and a large oval FoMoCo script logo. The elastomeric rings are bright orange. The element paper is pale yellow. The outer screen is made round punched holes mesh metal. Fram® was the supplier.

iii. Top

1. Stamped steel that showed no evidence of the metal being polished prior to plating. Metal defects such as "Lüders' lines" (McGraw-Hill Dictionary of Scientific & Technical Terms, 6E, Copyright © 2003. Lüders' lines[′lüd•ərz ‚līnz] (metallurgy) Surface markings on a metal caused by flow of the material strained beyond its elastic limit. Also known as deformation bands; Hartmann lines; Lüders' bands; Piobert lines; stretcher strains.) and waves or wrinkles are not uncommon. Examples have been seen where the raw material was either not wide enough to make a part or the material had slipped to one side in the die such that a small straight edge gets left at the extremity of the diameter. All parts have four (4) each round surface shape defects. The stamping die had four ejection pins to help remove the freshly stamped part from the die. The contours of the ends of the ejector pins rarely matched the contours of the lid well and something didn’t match at all. These die ejector pins produced round defects in the part. (Refinished original parts are easy to spot because platers affect these pin marks during their rework and often eliminate them entirely. This makes replated originals look like reproductions that don’t have the pin marks.) Both sides of the part received very thin nickel plating. The top side received a very thin to thin layer of chromium plating. Nickel plating is yellow in comparison to chromium plating so areas not over coated with chromium or coated thick enough to hide the yellow color will exhibit a yellow coloration. Sometime yellow areas are exhibited on the top appearance surface due to poor manufacturing quality control. Fit and finish just didn’t seem to matter at the time. The filter element side may or may not have some chromium plating on it. There is normally a round area under where the securing wing nut goes that shows little or no chromium plating. It looks like a plating mask or hanger created the effect of a yellow circular area under the wing nut.

2. Corrosion problem: The plating system used on these parts provided very little corrosion protection. Finding a used lid with zero blistering in the plating is rare. A single event that left chemicals or water standing on the lid would have most likely created the first blistering. Failure mode starts off as extremely small blisters under the plating. The blisters grow as rusting under the plating increases and eventually rupture to show red rust. Over time some lids became nearly 100% involved in red rust with little or no plating left.

3. Decals. The typical new Cobra, based on new car road test articles, had two common Ford decals on these air cleaner lids. The larger of the two was the "AUTOLITE® SPARK PLUG" advertisement in color. The other smaller was a "FOMOCO REPLACEMENT PARTS" advertisement. One original period picture shows a lid in a new Cobra missing the smaller decal. A missing decal must not have been considered important enough to replace the part back then.