Sorry, not what the workers wore, but the spray equipment.

Equipment would likely differ depended on what sound deadener was being applied. Trunk front wheel wells, interior door, interior quarter panels, rear wheel wells and inner quarter panels to name some of them.

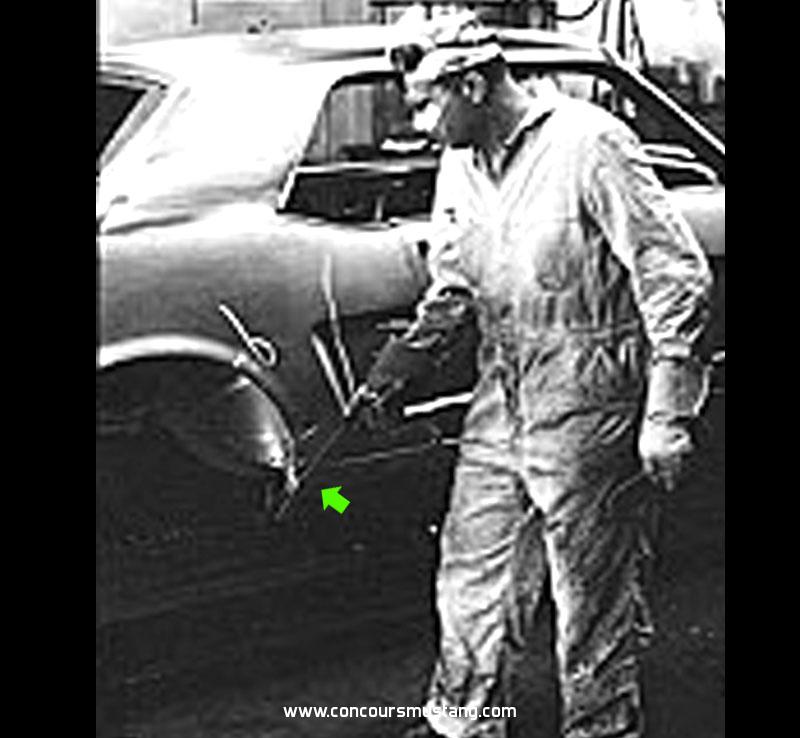

Only picture I could come up with is from a proof of a set of negatives from likely 65 Dearborn Assembly plant. This worker looks like he is using a long wand with an angle head to spray in and up to apply the sound deadener to the rear wheel well. This is likely, IMHO the same worker and tool that he would have applied the sound deadener to the trunk quarter panel surfaces at the same station.

As anticipated he lacks much of what would be expected in the years that follow as far as personal protective equipment. Has a fixture that held a pad up covering his nose, a cap, some glasses (he's not using), gloves and coveralls

Hope this helps