Holley(R) Le Mans Primary Fuel Bowl Bypassing Accelerator Pump Inlet Check Valve Assemblies

If you use a Holley Carburetor Company(R) 4V carburetor model, an original assembly line or genuine factory built service unit, that used the original design racing "center inlet" fuel bowls (a.k.a. Le Mans bowl at a later date) this subject may be of interest to you.

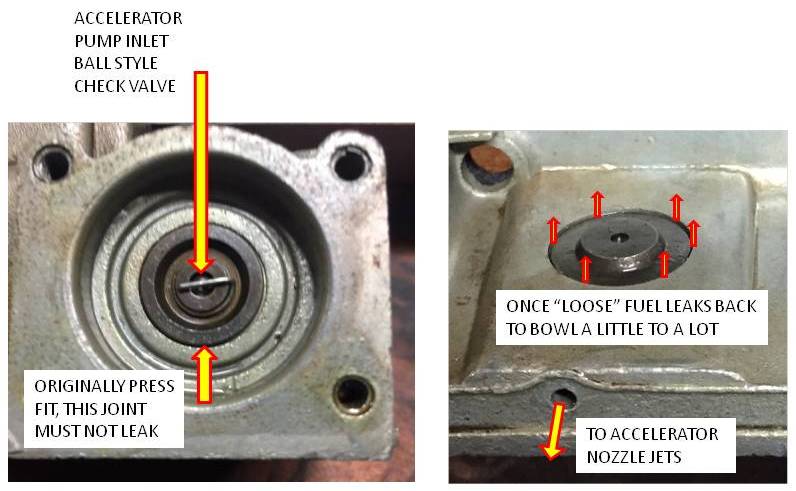

Multiple Ford and a few Chrysler racing carburetors used these type bowls 1963-1970. The primary fuel bowls of the original center inlet design (a.k.a. Le Mans bowl design) created for Ford racing has a modular or cartridge design press in check valve assembly in their floors for the accelerator pump system. The valve assembly was pressed into a passage bored into the floor of the bowl. No sealer was used. A tight press fit was the only protection against fuel going around the insert and instead of out to the engine.

Over time valve inserts that were leak free for the first few decades of use may become loose enough to start letting fuel bypass their valve inserts. They can get loose enough to rattle or worse. My theory is that the zinc alloy of the bowl casting and the brass alloy of the insert have such different coefficients of thermal expansion and contraction that the relatively hard brass part stretches the bore in the zinc floor wall slowly over time. I have come across inserts that became loose enough to easily pop out of the bowl floors. Just because any given assembly was leak free last year does not mean that is still leak free this year. In the 1980s I developed fine tuning for the R-3259-1AAS unit installed by a prior owner’s Shelby dealer in our black car in the 1967ish time frame. One spring I noticed that the engine was having a brief transient lean condition during every acceleration period; a lean stumble. I removed the carburetor and quickly found the problem. The accelerator pump inlet check valve insert was now leaking back to the bowl, a lot. It was not leaking when I took an afternoon to install an ethanol tolerance accelerator pump diaphragm a few years before. I have been testing Holley inlet check valves since the mid 1970s. If I have a primary bowl off for any reason I will test the valve. Of course I test the valves in every Holley 2V or 4V carburetor I have ever serviced since the 1970s. Carl’s Ford Parts sells replacement bowls with a Ford style one piece silicon rubber valve (a.k.a. umbrella valve) that is practically failure proof. I bought one of Carl’s bowls and the performance of my car’s carburetor was back to excellent.

In my contacts with others that service, repair, or restore carburetors with these type bowls I found that:

a) many did not care as long as the insert literally did not fall out (which has happened). Either they did not test such things or if they did, they did not act on what they found. I find that attitude appalling. Contracted to repair somebody's carburetor, often at significant cost to the owner, they just ignore the issue. I have found this loose leaking insert issue with units “restored” (made to look pretty) by world famous shops! In one case I was asked to help with a freshly restored carburetor that was as done better than typical finishes and correct parts wise but the owner reported a horrible acceleration stumble once the carburetor was back on its engine. The restorer indicated that the owner was doing something wrong or the engine had some vacuum leak or ignition problem. The owner asked me to find out what was wrong. The accelerator pump check valve insert was very loose. At least half of each pump stroke volume just went around the valve and back into the bowl. I swapped in one of Carl’s bowls with an umbrella valve and the owner reported back that his engine now performed great.

b) some have resorted to some type non-metallic filler to "glue in" the insert and or just seal it. "Red" grade thread locking compounds, fuel tank sloshing type sealer compounds, and various two component hardening organic compounds have been used.

c) some of us have purchased new replacement bowls from Carl's Ford Parts. Carl is the go to guy for many parts Holley® will no longer service. Call or e-mail Holley and they will redirect you to Carl. The new replacement bowls have updated the accelerator pump system to include the Ford 2100/4100 silicon rubber "umbrella" valve. It was a Ford carburetor exclusive for decades. The umbrella valve is almost idiot proof and chemically nearly indestructible. I have never heard of a single performance issue with them with any kind of fuel mix. Ford did a real good job in 1956 including the design in its carburetors.

d) repurposing a rear bowl is another direction to arrive at a permanent solution. Secondary bowls, originals or reproductions, were made with only semi-finished accelerator pump features. A little bit of machine shop time to drill the passages required to install an umbrella valve and a path to the main body and presto a genuine 1960s secondary bowl with appropriate patina retasked to be an upgraded primary bowl.

e) the other idea I have had, which would be relatively expensive time and money wise, would be to replace the insert with a piece of wall cut from a junk fuel bowl, get it welded in (Not everybody has the materials and skills to weld on thin wall zinc die castings but it can be done.), and then machine new chamber floor to the umbrella valve required configuration. Thermal masking of most of the bowl should preserve its color and patina.