Not sure how your going through the process but if your not shooting the car you might want to check with your paint or body guy to see what they have had success with and like to shoot over

Here are some pictures showing the final look of the process and also a couple of pictures showing the brazed spots you may want to reproduce on the car. Hope these help you and others

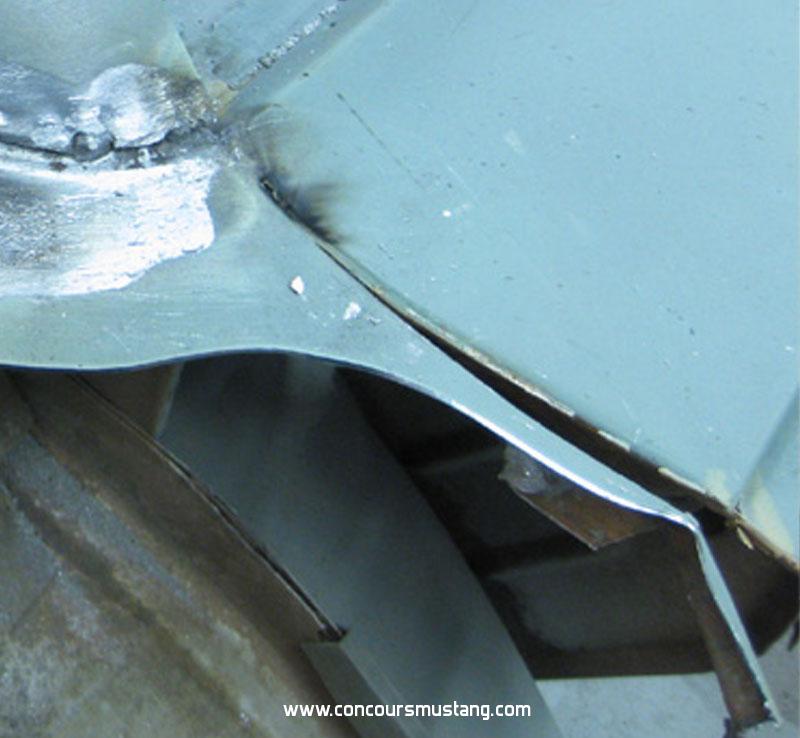

Rocker to quarter panel

Brazing at rear wheel well lip

Filler panel forward of trunk seam

Some times the brazing did not fill the gap completely so when the workers ground down the weld it was still visible at one or both ends. Seen it more often at the rear end of the seam as shown in the pictures below.

And a shot of the filler panel gap when pulled apart showing the small amount of sealer that was there - yes it has chipped and fallen off along the edge in a couple of spots . Not much of a gap between any of the panels to hold much sealer