There was a discussion that started over on one of the other forums and as part of the discussion I did a survey through my collection of pictures. While I was at it (since the subject has come up a number of times over the years) I went through all of the plants and this time noted if the cars had AC or an oil cooler or neither thinking that maybe one or more of these options would affect the workers choice when it came time to bolt in the horns. AC installation means that an additional bracket be installed between the horn and the radiator support while the oil cooler option or for 69 Boss 302 they are just mounted as if the cars were going to be equipped so with a reinforcement on the back side of the radiator support to support the additional weight of two holes on that side.

My findings were as follows. I limited my survey to only unrestored cars and those that showed no apparent signs of removal or possible replacement. Of course over time and possible maintenance false positives can be created but in total I think we can see or find patterns indicating typical or normal methods that were used

69 Dearborn Non-AC Non Drag Pak - 91% Installed from engine side

w/ Drag Pak - 100% Installed from the grill side

w/ AC - 75% Installed from engine side

69 San Jose Non-AC Non Drag Pak -95% Installed from the grill side

w/ AC - 67% (Only 3 Total not really enough) Installed from engine side

69 NJ Non-AC Non Drag Pak - 81% Installed from engine side

w/ Drag Pak - 100% Installed from the grill side

w/ AC - Mixed and not enough samples

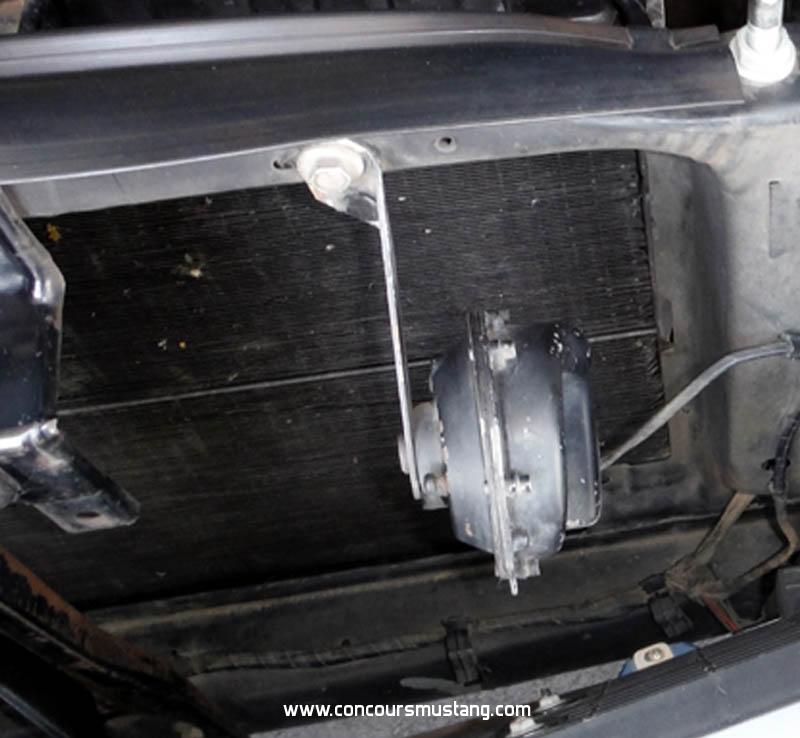

Some pictures to illustrate

Dearborn - No AC or No Oil Cooler San Jose - No AC or No Oil Cooler

San Jose - No AC or No Oil Cooler  Dearborn - With AC

Dearborn - With AC  San Jose - With AC

San Jose - With AC  Dearborn - With Oil Cooler

Dearborn - With Oil Cooler

Will be following up in the next week or so a similar survey of 70 Mustangs to see what that may uncover