If I may ask next for some reference of the firewall sealer and sound deadener pls ? On the fender aprons as I understand I just need sealer before paint and sound deadener comes after paint and assembly, so if you can hep me with the seam sealer req that would be great !

As far as the firewall sealant - does your car have AC. Might be able to focus a little better if I can find some examples

For the wheel wells, borrowing from what we see in other adjoining years at that plant and 67 we can get a basic idea of where seam sealer was placed before the body color was applied

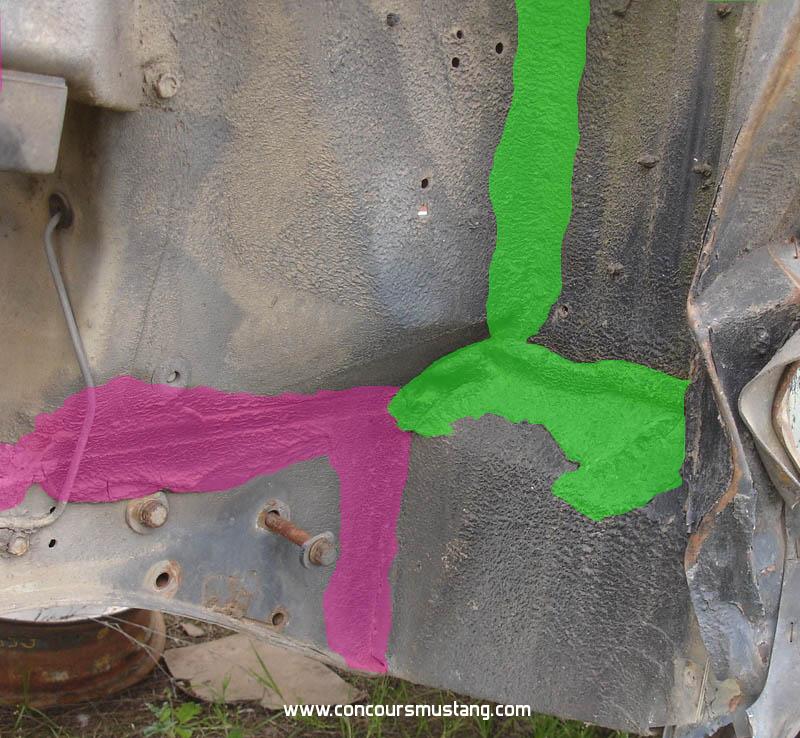

Basically seams got sealed along the firewall (in wheel well) to inner fender panel and across the top of the torque box. These seams are marked in purple in the pictures below.

Along with those but after painting the seams along the frame to floor (passenger side) as well as the torque box to frame on drivers side and along the inner fender panel to frame seam on both sides. These seams are marked in green below. Originally it was difficult to determine (with all the dirt and crud these examples are covered with) if this additional seams were covered before body paint was applied or if afterwards - with the front wheel well sound deadener was applied. For others reading this thread It appears that during the time where you car was built there was a couple of other seams that got sealed that were "skipped" later in production at Dearborn so if you have a latter built car one would not expect to find this detail

For this plant and time period I believe these last seams were applied after body color and likely when the front wheel wells were sound deadened. Reason is that the one pattern on the drivers side goes over the brake line directly in front of the rear pattern. we also see where the product's down ward flow was stopped by the one upper steering box bolt and some suggestion at the forward inner picture where the bumper bracket was in place Would be nice if I had an example with body color showing over all of these surfaces, would make this stand out more, but they are just too dirty to see that detail.

Same with this forward section of the inner fender panels - applied with the front wheel well sound deadener

Passenger side - Used a later example but will add in the horizontal seam sealer to illustrate

Hope this helps