Update on dry ice blasting experiment.

Bobby Crumpley arranged a dry ice blasting test cleaning job for me. The sample was a Ford 4100-A carburetor main body. I dismantled a carburetor and did no cleaning of the body in any way. The carburetor core was an extra nice one that had no signs of every being chemically or mechanically cleaned before.

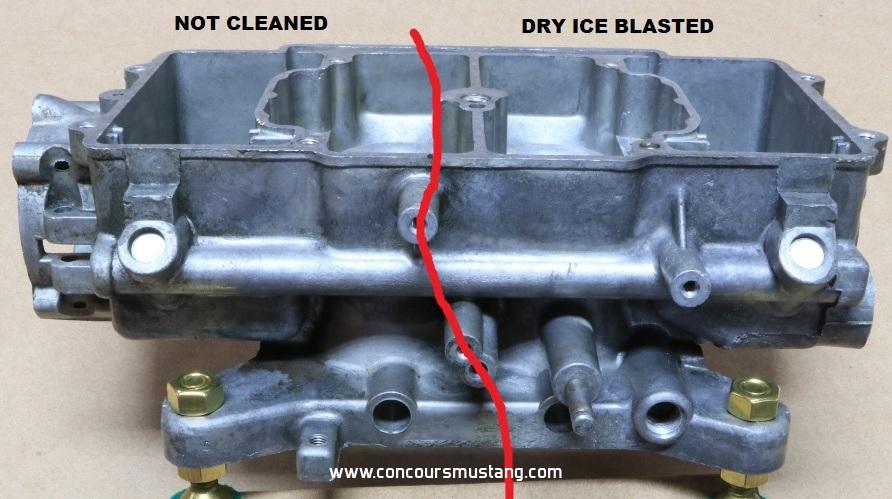

The experiment was to dry ice blast one end of the body and leave the other as received. The results were not as dramatic as I had hoped.

The cleaned areas came out looking like just manufactured everywhere the aluminum was protected from corrosion. Protection could be by a complete gasket seal of a surface, oily grime, tight fit like screw threads, and or fuel varnish. The economy valve boss looks like just machined where the ring gasket for the valve and the valve protected it. The black pressed paper gasket Ford used apparent took up water and allowed the dark gray corrosion film to form on the rest of the machined face. The dry ice blasting did not remove the rough feeling gray corrosion products.

The yellow and violet blue iridescence left over from the original manufacturing process was not disturbed by the dry ice blasting and locations projected by grime cleaned up well. Most "cleaning" methods would remove the iridescence. None of the tiny surface defects from tool marks and molten metal flow lines were changed in any way.

Right side, all areas with no protection from corrosion darkened in use and are still dark in dry ice blasted areas. Any surfaces protected from corrosion looks very much like they were freshly made and are much easier to see in person.

The experiment was not a total disappointment. In the past I have tried some kinds of mineral acids and bases to try and remove the dark corrosion byproducts on die cast aluminum carburetor parts without success. Some do little or nothing and some darken everything it touches more. So the hunt for a great cleaning method continues.