A method for removing straight oil fill tubes from Ford FE engine aluminum intake manifolds.

I rarely do anything with FE engines but I have struggled a few times on how to remove the oil fill tubes from factory aluminum intake manifolds without adding damaging the intake or oil fill tube. Back in 2011 when I was asked to clean up and service the entire induction system for a CSX31xx series 427 Cobra the tasks included having to deal with a damaged rusty tube and baffles assembly. The induction system had been removed from the engine in 1968 and stored in a commercial shop unprotected from shop grime (grinding dust, paint droplets, welding dust, and oils for example) until 2005 when the current owner of the car rescued the induction system. I was tasked with cleaning it up.

Other than being very dirty and the carburetors had been robbed of some small parts most of the system was in decent condition under the crud. The exception was the oil fill tube pressed into the intake manifold. The tube had an edge bent in at the top opening and a big dent in the side wall about half way down. Both baffles were jammed to the bottom and all three steel pieces were rust covered. The rust was not real deep except for a small lightly pitted area.

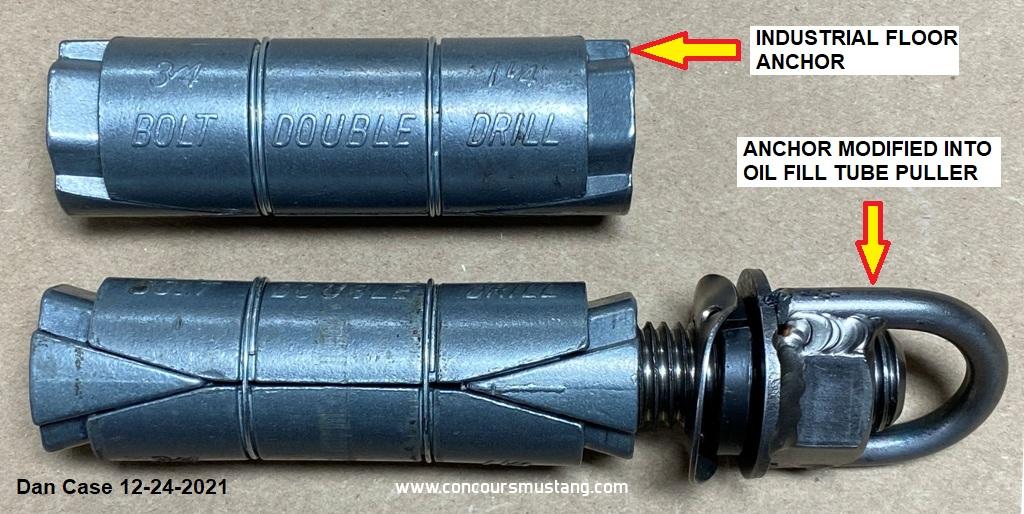

I tried finding a new old stock tube exactly the same in every way. Like most Ford parts, designs and vendors changed from time to time and the version used in CSX3101-CSX3200 427 Cobras turned out to be very rare. I have seen one new old stock one for sale since 2011. The car owner wanted the original part for the car saved if possible. That meant getting the already rusted damaged assembly out without adding any more damage. I studied the problem for a long time over several weeks. I started designing a tool to slip in inside the tube which would expand and use large surface area for gripping. I was not happy with what I came up with when I stumbled upon a hand full of large industrial floor anchors that were leftovers from some job or another. They were literally in a trash bin. I retrieved two and I was lucky, my problem was almost solved.

Starting with a thread anchor, I added a threaded stud, some washers, and a hex nut with a loop welded to it. The anchor slipped into the damaged tube even where it was dented. Tightening the stud expands the anchor. I hooked my body work slide hammer to the loop welded to the hex nut and the tube pulled out with no drama and no added damage to anything including my fingers.

I pushed the baffles out as they are only held by mild press fit. Standard metal working returned the baffles and tube to original shapes. I spent a little time trying to recreate the surface finish of the tube based on pictures I found of new old stock ones, indexed and pressed the baffles back into place, and pressed the tube back into the intake. The owner specifically wanted me to leave the tube bare so he could paint it with the same paint he wanted on the engine.

Commercial floor anchor and another I added pieces to in making up a oil fill tube puller.

The repaired tube reinstalled. Not perfect but another original part saved for the car it left Shelby American with. Paint will improve its appearance.