We discussed this feature earlier in another thread and the subject came up (related to San Jose production) on another site so wanted to extend the research to or members and include what data we could add to what I'm assembling. Same "rules" as the other surveys

This thread is posted to collect data related to the square rubber pad attached to the passenger side inner fender panel near the positive battery post and its mounting methods that applied to original 66 Mustangs build at all three plants. To participate please read the following. Thanks for your participation

- This is ONLY for 1966 Mustangs!!

- Participants need to provide the cars VIN (you can leave off the last two numbers if you choose to keep it private) and the projected build date from the original door/warranty tag. If you happen to have the original date of sale that might help also

- Look for features or clues of the panel being replaced. Not uncommon and often from acid/rust or accident damage

- We're interested in if there are holes for the plastic rivets in the rubber pad or not. If there are small round holes in the inner fender panel or not. If there are signs of four staple holes (very very small holes) in the inner fender panel. A combination of a number of these findings or something else.

- Picture would really help confirm things.

Again thanks for your time

++++++++++++++++++++++++++++++++++++++++++

San Jose results so far

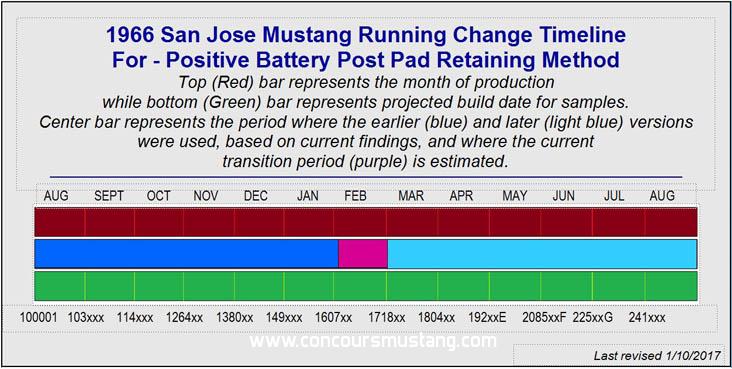

After looking at the date the follow pattern has appeared. Early in the production year San Jose stapled the battery post shield to the passenger side inner fender panel much like how the radiator seals were attached on those cars so equipped. A change was made and the new design meant that the shields would be attached using four plastic insert rivets. This design change was reflected much earlier in the year as the shields were provided to the factory with the four holes in the rubber pads.

During the transition it appears that San Jose workers continued to staple the shields as the pre punch (with holes for the plastic retaining rivets). Not sure if this is due to a lack of the rivets or having a mix of punched and unpunched panels available. Once all cars started receiving the punch inner fender panels the rivets were used consistently through the rest of production.

The transition period at this point appears to be between 6R164xxx and 6R172xxx

So since cars were not in sequential order and cars completed (documented) on the same day could have a range of sequential numbers by as much as 4,000 units I would say that this is as close as we can get given today's available information and limitations.